BLOG

Aug 14,2025

CNC transformer winding machine: a revolution in coil manufacturing driven by digital technology

Closed-loop digital tension control: Utilizing a German HBM tension sensor (accuracy ±0.2g) and a PID real-time adjustment algorithm, the servo motor dynamically compensates within 10ms when enameled wire tension fluctuations exceed ±5%. This ensures a stable tension of 2-5g when winding 0.08mm thin enameled wire, reducing the wire breakage rate from 1.2% with conventional equipment to 0.05%.

Read Full Article →

Aug 06,2025

Portable busbar punching machine: an efficient tool for power field operations

Fast Positioning and Intelligent Error Prevention: Taiwan's Zhiwei SH-70A machine utilizes a laser positioning module and edge gradient analysis algorithm to automatically calibrate punching positions, eliminating the problem of center deviation caused by manual experience in traditional equipment and reducing defect rates by 40%. Jinan Fengyao's FY-60 machine is equipped with a dual-axis inclination sensor that monitors the busbar placement angle in real time. When the deviation exceeds ±0.5°, the machine automatically shuts down and issues an alarm to prevent punching deformation.

Read Full Article →

Aug 01,2025

CNC busbar cutting machine: a precise blade for intelligent manufacturing of power equipment

High-precision motion control and stable clamping: Germany's Benn's BP-6000 machine utilizes a German-style fixed-edge clamp design, capable of reliably processing narrow busbars as small as 10x3mm. Combined with a servo motor-driven ball screw, it achieves a surface roughness of Ra ≤ 0.8μm and a burr residue of ≤ 0.02mm, a 60% reduction compared to the industry average. Jinan Zhenjie's ZJ-5000 series utilizes a gantry-style mechanical structure for simultaneous cutting and deburring operations, reducing the cycle time for a single workpiece to 40 seconds, a 50% improvement over traditional equipment.

Read Full Article →

Jul 25,2025

High-precision motion control and multi-station integration: Germany's Benn's BP-6000 machine utilizes a German-style fixed edge clamp design, capable of reliably processing narrow busbars as small as 10x3mm. Combined with an eight-position turret punching unit, it offers automatic die selection in ≤5 seconds and hole pitch control accuracy of ±0.1mm. Jinan Zhenjie's ZJ-5000 series utilizes a gantry-style mechanical structure to enable simultaneous punching, shearing, and chamfering operations, reducing the processing cycle for a single workpiece to 40 seconds, a 50% improvement over traditional equipment.

Read Full Article →

Jul 15,2025

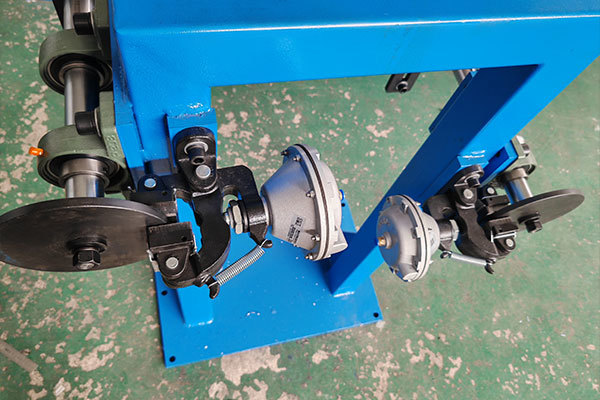

Fully automatic transformer coil winding machines, core equipment in transformer manufacturing, are undergoing a revolutionary upgrade from traditional hydraulic drive to fully servo-based intelligent control. For example

Read Full Article →